The safety of ironworkers is a paramount concern within the

construction and ironworking industries. Challenges are multifaceted;

luckily, fire-resistant clothing protects against on-site hazards.

Ironworkers regularly encounter sparks, flames, and heat, making it

imperative for them to understand and utilize protective gear. We will

take an in-depth look at the kinds of fire-resistant clothes ironworkers

wear, the features to prioritize when selecting these garments, and how

to maintain their protective qualities.

The Role of Fire-Resistant Clothing in the Ironworking Industry

Fire-resistant

(FR) clothing is a necessity for ironworkers who face a range of

dangers on the job, like the risk of molten metal splashing onto them

and potential arc flashes. These hazards can cause significant injuries

and tragic fatalities. FR clothing acts as a second skin, providing a

critical layer of defense against burns in the event of an accident. By

understanding the role of FR clothing, ironworkers can make informed

choices on the clothing they wear to work and reduce the risk of

injuries on the job.

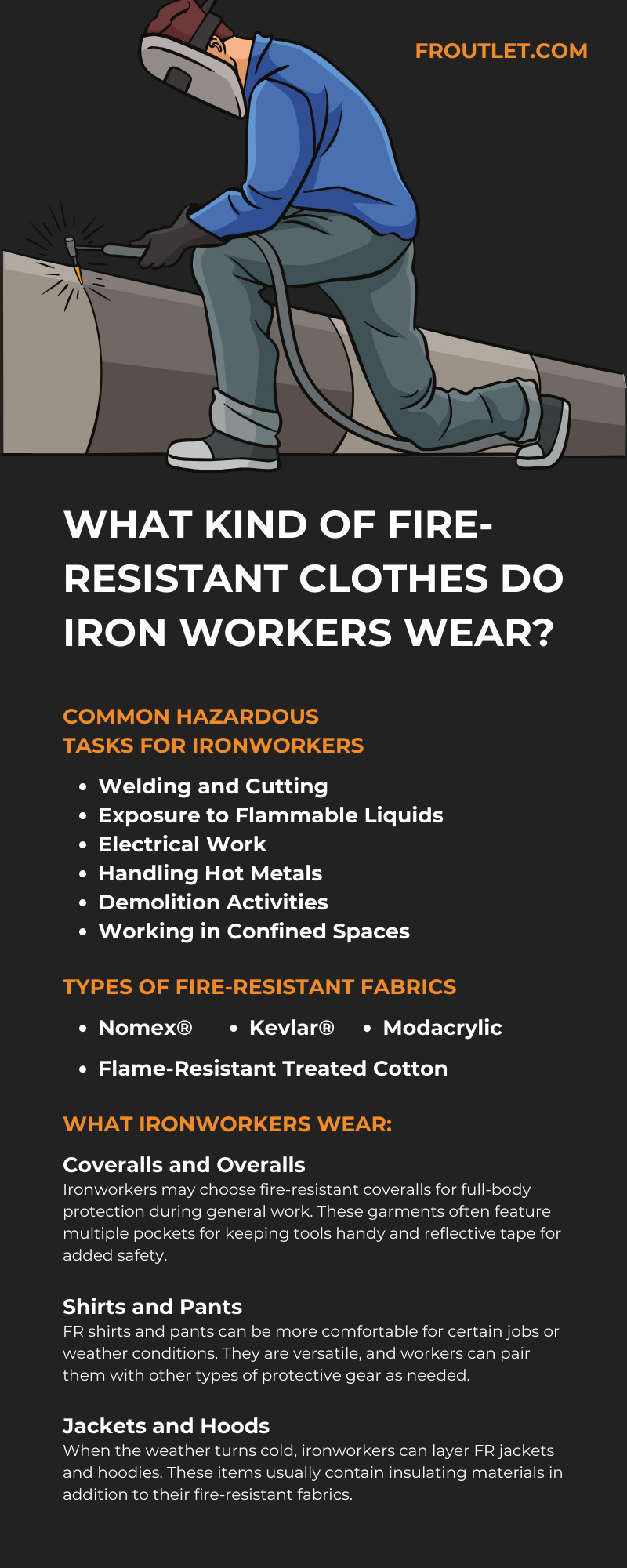

Common Hazardous Tasks for Ironworkers

Ironworkers

are regularly exposed to various hazardous tasks during the course of

their workdays. Understanding these risks is essential for preparing and

selecting the right fire-resistant clothing. Some of the most common

hazardous tasks include the following:

- Welding and Cutting: These tasks produce sparks and hot slag that can easily ignite non-fire-resistant clothing.

- Exposure to Flammable Liquids: Working near or with flammable materials and liquids increases the risk of fire-related accidents.

- Electrical Work: Tasks involving electricity may expose workers to arc flash hazards, leading to severe burns.

- Handling Hot Metals: Directly handling or being near hot metals can result in serious thermal burns.

- Demolition Activities: These can occasionally involve unexpected encounters with fire or sparks, especially when cutting through metal structures.

- Working in Confined Spaces: Confined spaces often have limited exits, increasing the risk of severe injury in the event of a fire.

Each

of these activities present unique challenges that require specialized

FR clothing. Ironworkers facing these circumstances need to ensure their

clothing can resist the intense heat generated from welding and

cutting, as well as the heat from environmental sources, such as

sunlight. By acknowledging these hazardous tasks and choosing protective

clothing that mitigates potential injuries, ironworkers can enhance

their safety.

Types of Fire-Resistant Fabrics

Several

types of fabrics offer fire-resistant properties, each suitable for

various ironworking conditions. Understanding these fabrics and their

benefits can make a huge difference for ironworkers on the job. The most

common materials include the following:

Nomex®

Developed

by DuPont™, Nomex® is an aramid fabric known for its exceptional heat

resistance. It is inherently fire-resistant, offering waterproof and

antistatic properties.

Kevlar®

Also created by DuPont™,

Kevlar® is an aramid fiber that provides significant tensile strength.

It is often blended with other materials to improve heat resistance in

FR clothing.

Modacrylic

A synthetic copolymer, modacrylic,

is inherently flame-retardant and maintains that property over numerous

washes. Due to its softness and comfort, manufacturers use it for

making protective workwear.

Flame-Resistant Treated Cotton

FR

clothing manufacturers treat regular cotton with chemicals to make it

flame-resistant. While it is less expensive than inherently

fire-resistant materials, it offers good protection and can be more

comfortable in hot conditions than other fabrics.

Key Features To Look for in Fire-Resistant Clothing

When

ironworkers select FR clothing, they should consider several crucial

features. They can protect themselves from the most common hazards with

these key attributes in mind:

Fit and Comfort

The clothing

must allow for the full range of motion without being loose, as extra

material can catch fire. Additionally, the fit should be comfortable to

support workers during long shifts.

Breathability

Given

the strenuous nature of ironworking, breathable fabrics are essential to

prevent overheating. Look for clothing with enhanced breathability to

stay cool, even in warm environments.

Visibility

High-visibility

FR garments are particularly important for ironworkers who often

operate at great heights. Such clothing ensures workers are visible to

others, which is critical for on-site safety.

What Ironworkers Wear: A Closer Look

Ironworkers

must wear a variety of FR clothing tailored to different aspects of

their work for maximum safety and comfort. Here are some examples of

popular FR clothing:

Coveralls and Overalls

Ironworkers may choose fire-resistant coveralls

for full-body protection during general work. These garments often

feature multiple pockets for keeping tools handy and reflective tape for

added safety.

Shirts and Pants

FR shirts and pants can be

more comfortable for certain jobs or weather conditions. They are

versatile, and workers can pair them with other types of protective gear

as needed.

Jackets and Hoods

When the weather turns cold,

ironworkers can layer FR jackets and hoodies. These items usually

contain insulating materials in addition to their fire-resistant

fabrics.

How To Maintain Fire-Resistant Clothing

Proper

care and maintenance of FR clothing are as essential as the initial

selection. Ironworkers should clean their garments with care to avoid

diminishing their protective properties. Here are some best practices

for laundry day:

Washing Guidance

Follow the

manufacturer’s recommendations for laundering, and avoid washing FR

garments with harsh detergents or fabric softeners that can compromise

their fire resistance.

Inspections

Regularly inspect FR

clothing for damage, such as tears or worn areas. Immediate repair or

replacement is necessary to ensure ongoing protection.

Storing

Store

FR clothing in a dry, cool area with minimal exposure to the sun and

away from potential contaminants. Contamination can reduce the

material’s FR rating.

A Shared Responsibility for Workplace Safety

In

situations where the well-being of ironworkers is non-negotiable,

selecting appropriate FR clothing is a significant component of job site

safety. By understanding these facets of FR clothing, ironworkers and

safety professionals can create a work environment that secures the most

vital asset—human life. Employers and workers alike have a shared

responsibility to provide the necessary protective gear and preserve its

integrity.

Knowing what kind of fire-resistant clothes to wear

and how to maintain them ensures a proactive stance in safety. Whether

it’s a discussion on their flame-retardant capabilities or the long-term

benefits of care, every insight contributes to a safer, more informed

workforce. Through this collective knowledge, the construction industry

can build a future where each worker returns home unscathed, their

safety as ironclad as the structures they help to erect.